본문

Product Name: Yoko 1313

Dimensions: 1300 × 1300 × 600 mm

Components: Hinoki bathtub body, built-in interior bench

External steps are optional.

Features and Benefits

- Ultimate Healing Experience: Soaking in a Hinoki wood bathtub for a half-body bath

provides a healing experience far superior to a medicinal decoction.

- Refreshing Aroma: The natural scent of Hinoki helps clear the mind and promotes relaxation.

- Skin Benefits: The oil in Hinoki wood (Cypress oil) is effective in treating skin issues like acne and atopic dermatitis.

- Premium Quality Wood: Only the finest, knot-free Hinoki wood, sourced from 100-year-old trees in Japan, is selected for this product.

- Aesthetic and Functional Design: The wood’s texture and the bathtub’s functionality are harmoniously integrated into a horizontal (Yoko) design, creating a bright and beautiful appearance.

- Maintenance Note: As a natural wood product without varnish or water-repellent treatment, discoloration (due to mold or contaminants) may occur. Regular cleaning and maintenance

are necessary to keep it in pristine condition. Minor stains can be removed by sanding after drying, and severe stains can be disinfected with vinegar or alcohol. Early discoloration

can be addressed quickly with bleach spray (ensure to rinse and ventilate after cleaning).

Patent Technology Applied

1. Double-Layer Waterproof Structure: A waterproof bathtub is embedded in the middle of the bathtub, ensuring no leakage concerns. The waterproof tub is made of ABS plastic

and aluminum, and the entire structure is wrapped in Hinoki wood, using HB Hanarobath's exclusive patented technology.

No Adhesives Used: The panels are joined together without using adhesives, providing a secure and eco-friendly construction.

2. No Adhesive Used in the Assembly

Unlike common bathtub manufacturing methods that use chemical adhesives to bond wooden slats together like plywood, our method avoids the use of any adhesive. In traditional methods, chemicals can dissolve into warm bath water, causing potential health concerns.

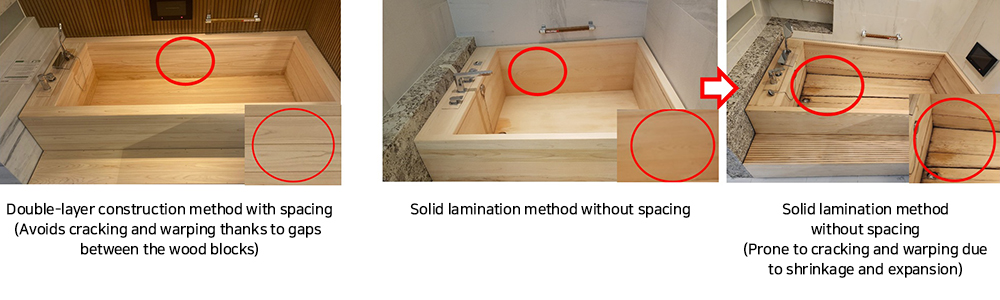

3. No Cracking or Warping

Our method creates bathtubs without any cracking or warping. By leaving gaps between each wood piece, the expansion and contraction of the wood do not interfere with each other, preventing any distortion or cracking. These gaps also allow the wood to "breathe," extending its lifespan. In contrast, traditional laminated plywood construction, which uses wood pieces of different properties, often results in warping and cracking due to the forces of expansion and contraction, especially at the weakest parts of the wood.

4. Replaceable Parts for Easy Maintenance

Our bathtubs are designed for easy disassembly and reassembly, allowing for partial or complete replacement without the need to move the bathtub. This feature makes it easier to replace damaged sections due to wear or contamination.

Problems with Domestic Hinoki (Japanese Cypress) Bathtubs

1. Use of Chemical Adhesives

The reason people choose Hinoki (Japanese Cypress) bathtubs is primarily due to the health benefits associated with the wood. However, during the bathtub manufacturing process, chemical adhesives are used to create laminated panels, which are then bonded together to form the floor and side panels. Some manufacturers even wrap the back with FRP for waterproofing and reinforcement. Since bathtubs are exposed to warm water for long periods, the chemical adhesives in these laminated panels can dissolve when exposed to water. Notably, laminated panels appear similar to plywood, with no visible joints between the wood slats.

2. Cracking and Warping of the Bathtub's Floor and Side Panels

Hinoki (Japanese Cypress) bathtubs repeatedly expand and contract due to the water. When multiple slats are bonded with adhesive to create a panel, the bathtub tends to crack or warp over time. During the drying process after use, the slats pull apart due to shrinking, and during the expansion process when the bathtub is filled with water, the weakest parts of the slats will buckle and distort.

3. Impossibility of Partial Replacement Due to Contamination

Hinoki (Japanese Cypress) bathtubs, being made from natural wood, are susceptible to staining and discoloration over time. Since these bathtubs are made as a single unit, it is not possible to replace individual parts if contamination occurs or if the wood darkens with prolonged use.

Movable Hinoki Bathtub

The movable Hinoki bathtub features a four-sided finishing style, meaning it cannot be installed exactly according to the dimensions of the on-site space. Instead, it is manufactured slightly smaller than the space and placed accordingly.

(Custom sizes can be produced upon order.)

If the bathtub is to be installed to fit exactly within the on-site space, it will be installed as a built-in style, not as a movable unit.

The custom-made Hinoki bathtub for specific spaces consists of three parts: the bathtub body, the top panel, and the front apron (skirt). These components are assembled on-site.

Installation Note: Installation requires additional costs for labor and a site visit. After the tile finishing is done, measurements will be taken, and production will take approximately two weeks before installation